Machine electrical components can be customized and upgraded according to customer needs.

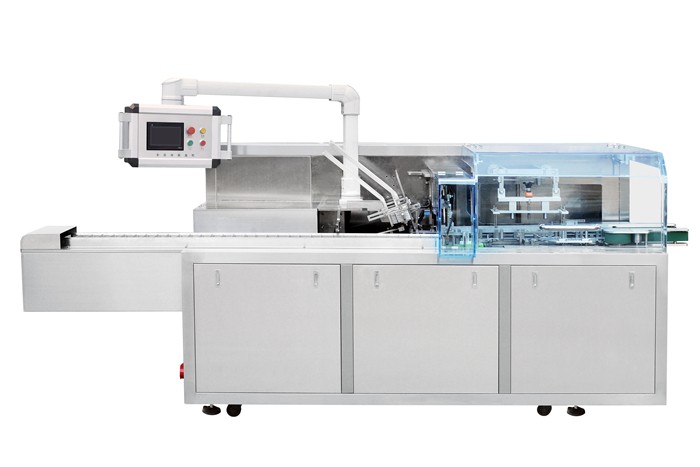

The boxing machineintegrates unpacking, packing, folding and sealing, with compact and reasonable design, simple operation and convenient maintenance.

High degree of automation: PLC programmable control system, man-machine interface displays parameters such as packing speed, quantity, automatic alarm for lack of boxes/bags, no product unpacking, failure reasons and other parameters.

The transmission and friction parts are strictly implemented in accordance with the standards, with less wear and tear in the later period, reducing the replacement of parts

The normally dismantling structure is easy to disassemble and connect, ensuring hygienic and convenient handling when changing shifts or changing products

|

Model |

KY200ZH |

|

Capacity |

30-60 boxes/min (Depend on the box size, product type and box thickness) |

|

Box size |

L:90-200mm;W:70-150mm; H:20-50mm (Can be customized) |

|

Paper type |

250-400g/² (Boxes need come with pre-folded over) |

|

Box type |

Gusseted tongue type; Glue spray type |

|

Count way |

Fixed number type; Numerable type; Manipulator counting |

|

Boxing way |

Ordely type; Unorderly type |

|

Air & Powder |

0.5-0.8Mpa; 0.3m³/min; 220V 50/60HZ; 2.0KW |

|

Work flow |

Box open-Bag packing -Check weigher- Counting – Boxing -Fold ears- Fold page – Gusseted tongue/ Glue spray – Finish |

Anhui packerpro Co.ltd

Anhui packerpro Co.ltd

.40.1.jpg)