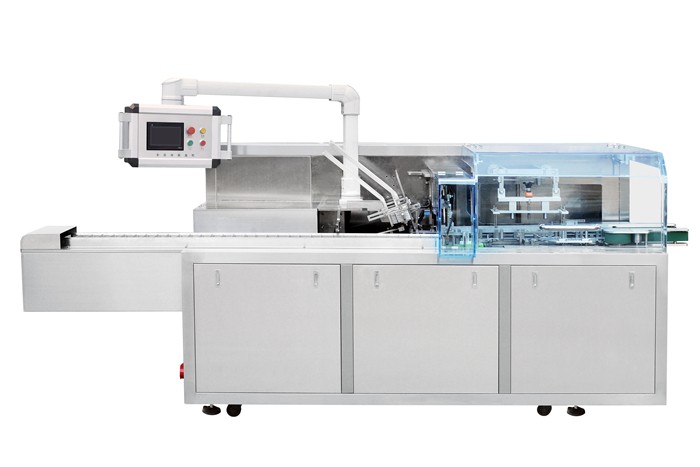

Adopt domestic and foreign PLC, cylinders, optics, touch screen, temperature controller, frequency converter, relays, servo motors, high quality power supply circuits;Use manual man-machine interface and automatic detection and alarm system program for this machine;

Be able to weight, bag-making, fill, sealing, cutting, lot number, cutting easy tearing notch, etc. Automatically;

Visible hopper with openable door

Servo Motor, good and fast speed and very high accuracy and more durable.

To have a color control system that can get the complete trademark design.

With Original Imported PLC Control System, make machine very good stability, good use, durable in using time

Material is stainless steel. Meet the standard requirements for food products and durable in using time.

|

Model |

KY840BY |

|

Lane number |

4-18 |

|

Filling Method |

1.Piston pump 2.Peristaltic pump 3.Ceramic pump 4.Rotary pump |

|

Capacity |

Max.50 cycle/min |

|

Bag size |

L:50-180mm;W:17-100mm |

|

Film width&thickness |

Max.840mm,0.07-0.10mm |

|

Sealing type |

Back sealing / Stick bag |

|

Cutting type |

1.Straight cutting; 2. Zig zag cutting; 3. Round cutting; 4. Die-cut |

|

Air&Power |

0.8Mpa ,0.8m³/min; 6.5kw |

|

DIM & WT |

1700*1600*2300mm; 900kg |

Anhui packerpro Co.ltd

Anhui packerpro Co.ltd

.21.1.jpg)